How Hitachi Air Conditioning Horsepower Conquers Extreme Piping Distances

In the intricate world of air conditioning, the casual observer often focuses on BTU ratings, sleek design, or smart features. Yet, for architects, engineers, and facility managers tackling large-scale projects, one critical factor often defines the feasibility and efficiency of a climate control system: the ability to handle long refrigerant piping distances. This isn’t just about moving the cooling agent; it’s about maintaining performance, ensuring system longevity, and delivering consistent comfort across vast or vertically challenging spaces.

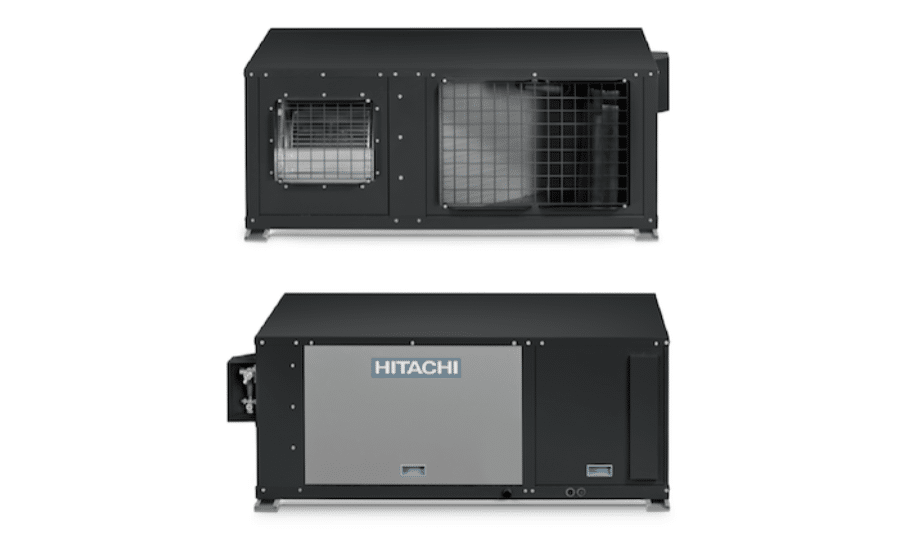

This is where Hitachi Air Conditioning distinguishes itself. Leveraging a sophisticated understanding of horsepower (HP) and an unwavering commitment to pioneering engineering, Hitachi has developed systems that set industry benchmarks for their ability to operate effectively over distances that would cripple conventional AC units. This detailed guide explores the nuances of AC horsepower, the inherent challenges of extended piping, and how Hitachi’s innovative approach not only overcomes these obstacles but redefines what’s possible in modern climate control.

Unpacking Air Conditioning Horsepower: More Than Just a Number

Before delving into the specifics of long piping, it’s crucial to understand what “horsepower” signifies in an air conditioning context. Unlike the horsepower of a car engine, which directly relates to its motive power, AC horsepower primarily refers to the electrical power consumed by the compressor motor. While not a direct measure of cooling capacity (which is typically expressed in BTUs, tons, or kW), the compressor’s horsepower is fundamental to its ability to:

- Circulate Refrigerant: The compressor is the heart of the refrigeration cycle, responsible for compressing the refrigerant gas, increasing its pressure and temperature, and driving its circulation through the system’s coils and lines.

- Overcome Resistance: As refrigerant travels through pipes, it experiences friction and pressure drops. A more powerful (higher HP) compressor is better equipped to overcome this inherent resistance, especially over longer distances.

- Maintain Pressure Differentials: The efficiency of heat exchange relies on significant pressure and temperature differences between the indoor and outdoor units. The compressor’s HP is crucial in maintaining these differentials consistently.

In essence, a robust, intelligently managed compressor horsepower is the backbone of an efficient and reliable air conditioning system. Traditional fixed-speed compressors operate at a constant HP, leading to on/off cycling and energy waste. Hitachi, however, utilizes advanced DC Inverter technology, allowing its compressors to modulate their HP output precisely. This means the compressor can ramp up its power when demand is high or piping resistance is significant, and scale back down when less cooling is needed, resulting in unparalleled efficiency and adaptability.

The Silent Nemesis: The Challenges of Long Piping Distances

Imagine a marathon runner. They can maintain a sprint over 100 meters, but expecting them to sustain that same speed and effort over 42 kilometers is unreasonable. Similarly, the physics of refrigeration introduce significant challenges when refrigerant has to travel extended distances:

- Refrigerant Pressure Drop: This is the most significant hurdle. As refrigerant flows through long pipes, friction with the pipe walls causes a reduction in pressure. This pressure drop directly impacts the compressor’s ability to move refrigerant efficiently, requiring it to work harder and potentially leading to a loss of cooling capacity at the indoor units.

- Oil Return Issues: Refrigerant oil, essential for lubricating the compressor, circulates with the refrigerant. In systems with long horizontal or severe vertical runs, especially if the flow rate is insufficient due to pressure drop, the oil can “pool” in certain sections of the piping. This not only starves the compressor of lubrication (leading to wear and potential failure) but also reduces heat transfer efficiency in the evaporator.

- Capacity Degradation: Excessive pressure drop and poor oil return inevitably lead to a reduction in the system’s net cooling or heating capacity. The indoor units simply won’t be able to deliver the rated performance, leaving occupants uncomfortable.

- Increased Energy Consumption: To compensate for pressure drops, a conventional compressor might have to run longer or harder, leading to higher energy bills.

- System Instability and Reliability Concerns: Poor refrigerant distribution, fluctuating pressures, and inadequate oil return can destabilize the entire system, leading to error codes, frequent breakdowns, and a shorter operational lifespan for the equipment.

- Logistical & Design Constraints: In high-rise buildings, sprawling campuses, or complexes with distant outdoor units, the inability to achieve long piping runs forces designers into suboptimal unit placements, sometimes requiring multiple outdoor units or complex intermediary solutions, increasing installation costs and architectural compromises.

Standard split systems are typically limited to relatively short piping lengths, often between 15-30 meters (50-100 feet). Even basic VRF (Variable Refrigerant Flow) systems, while offering more flexibility, have performance degradation curves that become steep at their maximum specified lengths. This is precisely where Hitachi’s engineering prowess shines.

Hitachi’s Engineering Philosophy: Conquering Distance with Intelligent HP

Hitachi’s leadership in handling extreme piping distances isn’t accidental; it’s the result of a deliberate and integrated engineering philosophy centered around three pillars: advanced compressor technology, optimized refrigerant circuits, and sophisticated control systems.

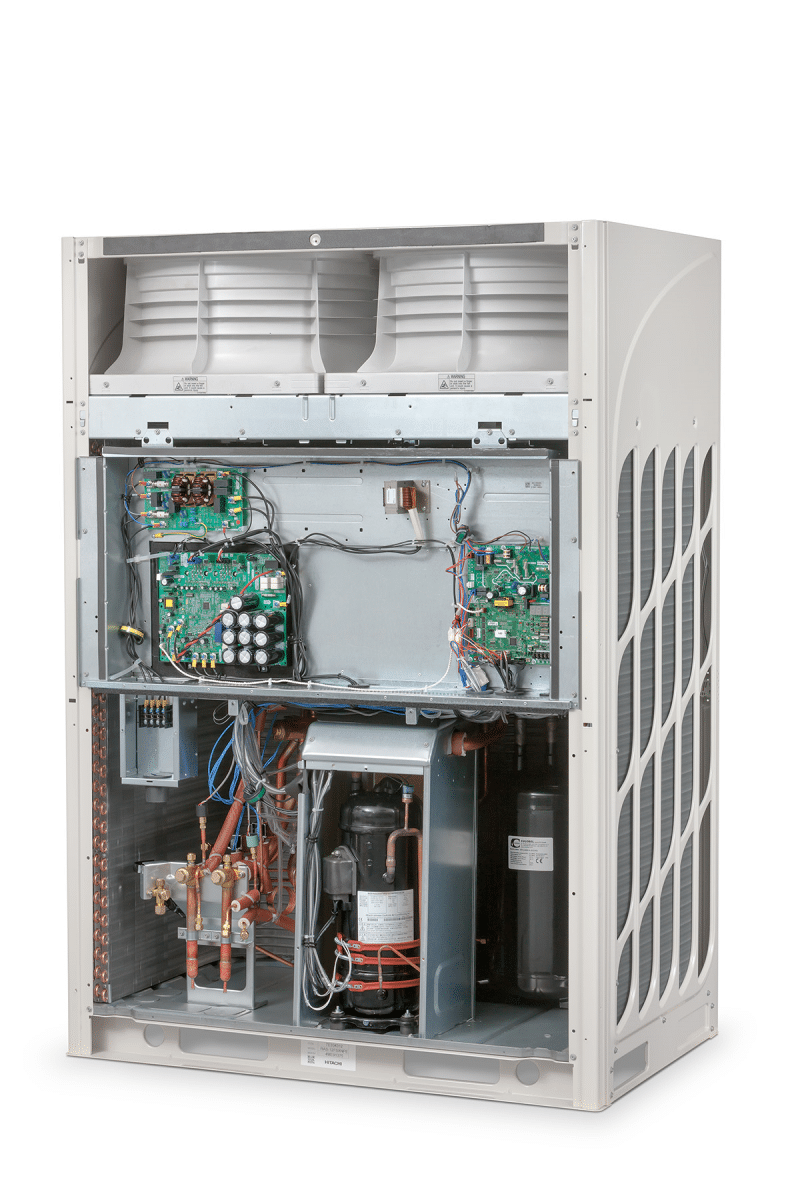

1. The Heart of the Matter: Revolutionary Compressor Technology

At the core of Hitachi’s long-distance capability lies its proprietary DC Inverter Scroll and Rotary Compressors. These aren’t just powerful; they’re intelligent powerhouses:

- High-Efficiency DC Inverter Motors: Unlike conventional AC motors, Hitachi’s DC inverter motors offer superior efficiency across their entire operating range. This means they can generate significant horsepower with less electricity, essential for maintaining performance over long runs without excessive energy consumption.

- Robust Scroll/Rotary Design: Hitachi’s compressors are built to withstand the rigorous demands of varying loads and pressures. Their scroll and rotary designs are inherently more efficient and durable than reciprocal compressors, particularly for applications requiring variable speed operation and high compression ratios.

- Precision and Control: The DC inverter drive allows for minute adjustments to the compressor’s speed and, consequently, its HP output. This precision enables the system to:

- Dynamically Compensate: As piping length increases and pressure drops, the compressor can intelligently increase its speed and effective HP to maintain optimal refrigerant flow and pressure differentials, ensuring consistent capacity delivered to the indoor units.

- Optimize Energy Usage: Instead of running at full throttle constantly, the compressor modulates its speed to match the exact cooling/heating demand and the specific conditions of the piping network, drastically reducing energy waste.

2. Mastering the Flow: Optimized Refrigerant Circuit Design

A powerful compressor is only as good as the system it drives. Hitachi’s engineers have meticulously designed the refrigerant circuits to complement their high-performance compressors:

- Advanced Oil Management: Hitachi often incorporates sophisticated oil recovery and return mechanisms. This can include specialized oil separators, intelligent oil return cycles, and optimized piping branch joints that actively guide oil back to the compressor, preventing pooling and ensuring critical lubrication, even over extreme vertical lifts (e.g., in high-rise buildings).

- Subcooling Circuits and Liquid Injection: Some Hitachi VRF systems feature advanced subcooling circuits or liquid injection technologies. These innovations ensure that the refrigerant reaching the expansion valve is in a highly subcooled liquid state, maximizing its cooling potential and significantly reducing the impact of pressure drops over long distances.

- Optimized Pipe Sizing and Configuration: While general principles apply, Hitachi’s systems are designed to operate efficiently with specific pipe diameters and configurations over extended runs, minimizing pressure loss through intelligent sizing recommendations and system architecture.

3. The Brains of the Operation: Intelligent Control Systems

Hitachi’s ability to conquer distance is significantly amplified by its state-of-the-art control systems:

- Adaptive Control Algorithms: The system’s microprocessor continuously monitors dozens of parameters – refrigerant pressure, temperature, outdoor ambient conditions, indoor loads, and compressor status. It then uses advanced algorithms to dynamically adjust compressor speed, electronic expansion valve openings, and fan speeds to maintain optimal performance and efficiency, even when faced with extreme piping lengths.

- Self-Correction and Diagnostics: Hitachi units are designed with robust self-correction capabilities. If minor pressure drops or anomalies occur due to long piping, the system can often compensate automatically, preventing capacity loss or system shutdowns. Comprehensive diagnostic tools also aid in troubleshooting and maintenance.

- Sophisticated Sensor Networks: A dense network of high-precision sensors strategically placed throughout the system provides real-time data to the control board, enabling precise adjustments and ensuring the system operates within its optimal envelope, regardless of external challenges posed by piping length.

How Hitachi’s HP Translates to Unrivaled Long Piping Capability

The synergy of Hitachi’s advanced compressor technology, refined refrigerant circuits, and intelligent controls culminates in concrete advantages for projects requiring extensive piping:

- Extended Maximum Total Piping Lengths: Hitachi VRF systems boast some of the industry’s most impressive maximum total piping lengths, often reaching over 1,000 meters (approx. 3,280 feet) in certain configurations. This is significantly higher than many competitors and vastly exceeds standard split system capabilities.

- Impressive Vertical Separations: For high-rise buildings, vertical separation (the height difference between the outdoor unit and the highest/lowest indoor unit) is critical. Hitachi systems commonly support vertical separations of 90 meters (approx. 295 feet) or more, ensuring single outdoor units can serve numerous floors.

- Sustained Capacity Retention: While all AC systems experience some capacity degradation over distance, Hitachi’s intelligent HP management minimizes this effect. Their systems are designed to maintain a high percentage of their rated capacity even at near-maximum piping lengths, ensuring consistent comfort delivery.

- Exceptional Energy Efficiency (EER/COP) at Distance: By precisely modulating compressor HP and optimizing refrigerant flow, Hitachi units prevent the energy penalty often associated with long piping. They maintain superior EER (Energy Efficiency Ratio) and COP (Coefficient of Performance) even under demanding conditions, leading to lower operating costs.

- Enhanced Reliability and Longevity: The stable operation, efficient oil return, and precise control provided by Hitachi’s design reduce stress on components, minimize wear and tear, and significantly extend the lifespan of the entire system.

- Unrivaled Design Flexibility: Architects and mechanical engineers are liberated from the constraints of short piping, allowing for greater freedom in outdoor unit placement, preserving valuable ground-level space, and accommodating complex building designs without compromising HVAC performance.

Comparative Analysis: Hitachi vs. Other AC Units on Long Piping

Let’s put Hitachi’s capabilities into perspective:

| Feature/Metric | Standard Split Systems | Basic VRF/VRV Systems | Hitachi High-Performance VRF Systems |

|---|---|---|---|

| Max Total Piping Length | 15-30 meters (50-100 ft) | 100-200 meters (330-660 ft) | 1,000+ meters (3,280+ ft) |

| Max Vertical Separation | 5-10 meters (16-33 ft) | 30-50 meters (100-165 ft) | 90+ meters (295+ ft) |

| Capacity Retention @ Max Length | Significant degradation (20-40%+) | Moderate degradation (10-20%) | Minimal degradation (0-10%) |

| Energy Efficiency @ Max Length | Poor – higher energy consumption | Moderate – efficiency can drop | Excellent – maintains high EER/COP |

| Primary Limitation | Compressor power & pressure drop | Pressure drop & oil return | Technological frontier (industry-leading) |

| Ideal Application | Small homes, single rooms | Mid-sized commercial, multi-zone homes | High-rise, large commercial/campus, complex layouts |

While other manufacturers offer VRF solutions, Hitachi’s dedication to pushing the boundaries of compressor technology and control systems often results in higher maximum specifications and superior performance retention at those extremes. This difference can be critical for projects where every meter of piping length and every percentage of retained capacity matters.

Applications That Demand Hitachi’s Long Piping Prowess

Hitachi’s advanced AC systems are the ideal choice for a wide array of demanding applications:

- High-Rise Office and Residential Buildings: Where outdoor units might be placed on the ground or rooftop, requiring refrigerant to travel dozens of floors vertically.

- Large University Campuses and Hospital Complexes: Sprawling facilities with multiple buildings or wings served by centralized outdoor units.

- Industrial Facilities: Manufacturing plants or warehouses with vast footprints where indoor units need to be distributed across large areas.

- Hotels and Resorts: Extensive properties with numerous rooms and common areas, often with aesthetic considerations that demand discreet, distant outdoor unit placement.

- Shopping Malls and Convention Centers: Massive enclosed spaces requiring uniform climate control over expansive areas.

- Historical and Heritage Buildings: Where architectural preservation dictates that outdoor units cannot be visible or placed close to the building, necessitating long runs to less conspicuous locations.

- Data Centers and Server Rooms: Where precise temperature control is paramount and outdoor units may need to be positioned away from sensitive equipment or secure areas.

In these scenarios, the ability of Hitachi’s AC horsepower to effectively manage ultra-long piping distances translates directly into greater design flexibility, reduced installation complexity, optimized performance, and long-term energy savings.

Choosing the Right Hitachi System: A Partnership in Performance

Selecting an air conditioning system capable of handling long piping distances is a complex decision that requires expert consultation. It’s not just about the maximum stated length; it involves understanding:

- Building Load Calculations: Accurate assessment of heating and cooling demands for each zone.

- Architectural Layout: Detailed plans of the building’s structure, floor plans, and potential outdoor unit locations.

- Vertical vs. Horizontal Piping Ratios: The specific breakdown of elevation changes vs. linear runs.

- Local Climate Conditions: Extreme ambient temperatures can further stress systems.

Hitachi’s network of qualified engineers and distributors can provide comprehensive design assistance, ensuring that the selected system – from their renowned VRF series like Set Free to other specialized solutions – is precisely tailored to meet the unique demands of your project. They will help you navigate the specifications, optimize piping layouts, and ultimately deliver a climate control solution that performs flawlessly, even across the most challenging distances. Contact ACL for more info on Hitachi systems.